Predictive Maintenance Using Machine Learning

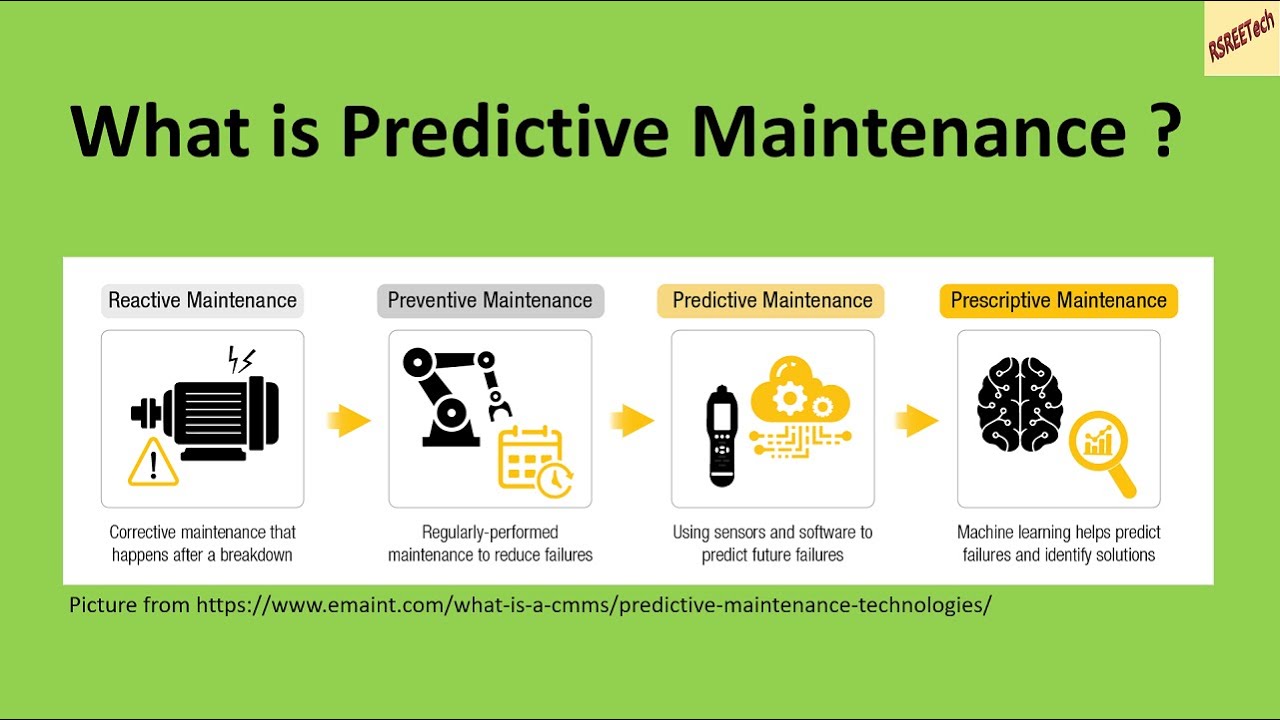

Predictive maintenance is a proactive maintenance approach that uses data and analytics to predict when equipment is likely to fail. By identifying potential problems before they occur, predictive maintenance can help organizations avoid costly downtime and unplanned repairs.

Machine learning is a powerful tool that can be used to improve the accuracy and efficiency of predictive maintenance. Machine learning algorithms can learn from historical data to identify patterns and trends that can be used to predict future outcomes. This information can then be used to schedule preventive maintenance tasks, optimize maintenance processes, and reduce the risk of equipment failure.

There are a number of different machine learning techniques that can be used for predictive maintenance. Some of the most common techniques include:

- Regression models can be used to predict the future value of a given variable. Regression models can be used to predict the remaining useful life of a piece of equipment, the likelihood of a failure, or the cost of a repair.

- Classification models can be used to predict the class or category of a given observation. Classification models can be used to identify equipment that is at risk of failure, or to determine the type of maintenance that is needed.

- Clustering algorithms can be used to group observations into similar clusters. Clustering algorithms can be used to identify patterns in equipment failure data, or to identify groups of equipment that are at risk of failure.

Machine learning can be used for predictive maintenance in a variety of industries, including:

- Manufacturing

- Energy

- Transportation

- Healthcare

- Retail

By using machine learning for predictive maintenance, organizations can improve the reliability of their equipment, reduce the cost of maintenance, and increase the uptime of their operations.

How Machine Learning Works for Predictive Maintenance

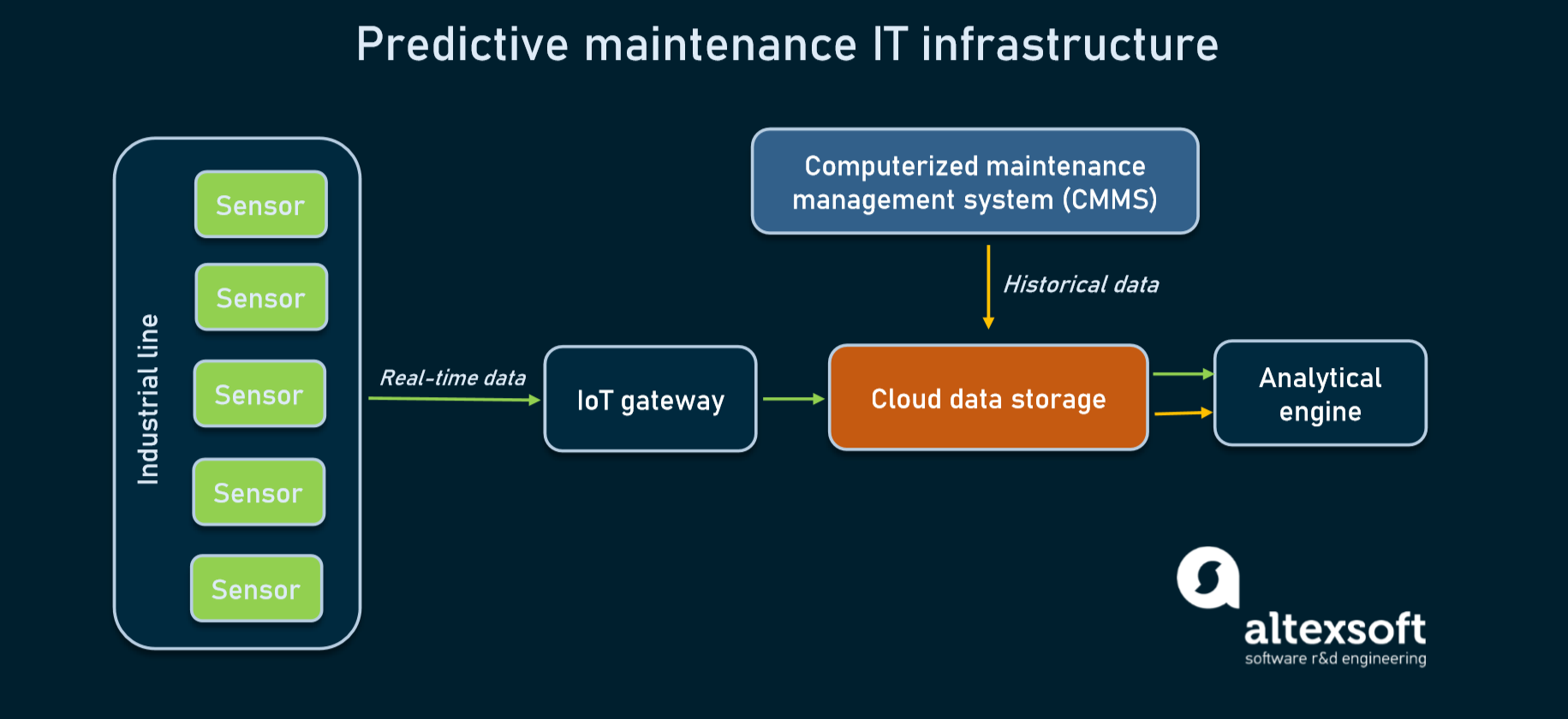

Machine learning algorithms are trained on historical data to identify patterns and trends that can be used to predict future outcomes. This data can come from a variety of sources, such as:

- Sensor data from equipment

- Log data from systems

- Service records from maintenance activities

Once the machine learning algorithm is trained, it can be used to make predictions about the future. These predictions can be used to schedule preventive maintenance tasks, optimize maintenance processes, and reduce the risk of equipment failure.

Benefits of Predictive Maintenance

Predictive maintenance can provide a number of benefits for organizations, including:

- Reduced downtime. By identifying potential problems before they occur, predictive maintenance can help organizations avoid costly downtime and unplanned repairs.

- Reduced maintenance costs. By scheduling preventive maintenance tasks, organizations can reduce the need for unplanned repairs. This can save money on parts, labor, and lost productivity.

- Increased uptime. By preventing equipment failures, predictive maintenance can help organizations improve the uptime of their operations. This can lead to increased productivity and profitability.

- Improved safety. By identifying potential problems before they occur, predictive maintenance can help organizations prevent accidents and injuries.

Challenges of Predictive Maintenance

There are a number of challenges that can be associated with predictive maintenance, including:

- Data availability. In order to train a machine learning algorithm, organizations need to have access to historical data. This data can be difficult to collect and may not be available in a consistent format.

- Data quality. The quality of the data used to train a machine learning algorithm can have a significant impact on the accuracy of the predictions. It is important to ensure that the data is accurate, complete, and up-to-date.

- Algorithm selection. There are a number of different machine learning algorithms that can be used for predictive maintenance. The right algorithm for a particular application will depend on the type of data available, the desired accuracy, and the resources available.

- Deployment and maintenance. Once a machine learning model has been trained, it needs to be deployed and maintained in production. This can be a complex and time-consuming process.

How to Implement Predictive Maintenance

Implementing predictive maintenance can be a complex process, but there are a number of steps that organizations can take to get started:

- Identify the assets that need to be monitored. The first step is to identify the assets that are critical to the business and that are most likely to fail. These assets should be monitored for signs of wear and tear, as well as for potential problems.

- Collect data on the assets. The next step is to collect data on the assets that are being monitored. This data can come from a variety of sources, such as sensors, log files, and service records.

- Choose a machine learning algorithm. Once the data has been collected, the next step is to choose a machine learning algorithm to train. The right algorithm for a particular application will depend on the type of data available, the desired accuracy, and

Post a Comment