Artificial Intelligence-Driven Predictive Maintenance for Manufacturing

Predictive maintenance is a proactive maintenance approach that uses data analysis to predict when equipment is likely to fail. By identifying potential problems before they occur, predictive maintenance can help to prevent unplanned downtime and reduce maintenance costs.

In recent years, artificial intelligence (AI) has become increasingly important for predictive maintenance. AI-powered predictive maintenance solutions use machine learning and other advanced analytics techniques to learn from historical data and identify patterns that can be used to predict future failures. This data can come from a variety of sources, including sensors, log files, and product usage data.

AI-driven predictive maintenance solutions offer a number of advantages over traditional predictive maintenance methods. These advantages include:

- Improved accuracy: AI-powered solutions can learn from more data and identify more patterns than traditional methods, which can lead to improved accuracy in predicting equipment failures.

- Earlier detection: AI-powered solutions can identify potential problems earlier than traditional methods, which can give manufacturers more time to take action and prevent unplanned downtime.

- Reduced costs: AI-powered solutions can help to reduce maintenance costs by preventing unplanned downtime and identifying problems that can be fixed before they become serious.

AI-driven predictive maintenance is still a relatively new technology, but it is quickly gaining traction in the manufacturing industry. As the technology continues to develop, it is likely to play an increasingly important role in helping manufacturers to improve their operations and reduce costs.

How AI-Driven Predictive Maintenance Works

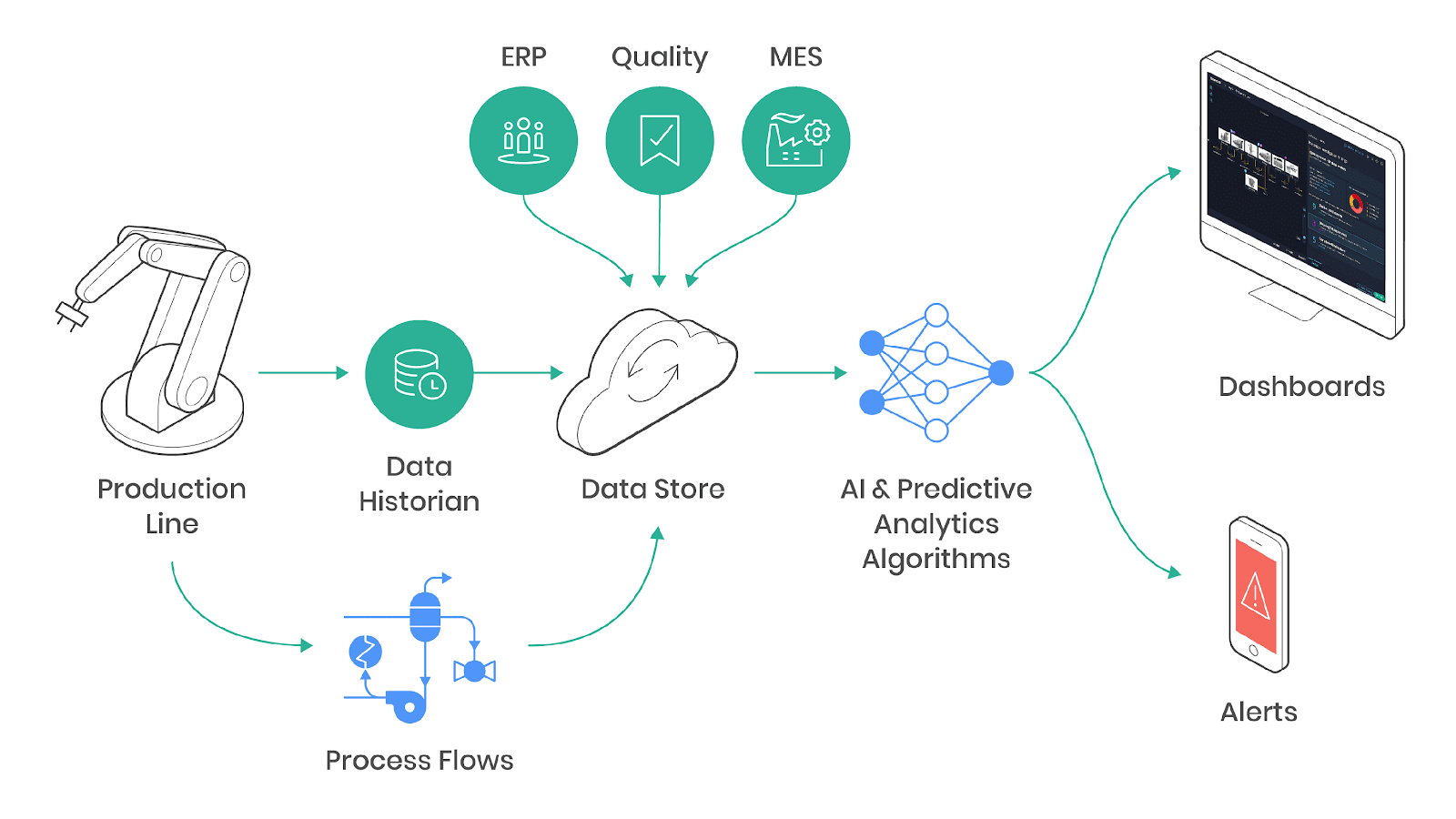

AI-driven predictive maintenance solutions typically use a combination of machine learning and other advanced analytics techniques to learn from historical data and identify patterns that can be used to predict future failures. This data can come from a variety of sources, including sensors, log files, and product usage data.

The first step in the process is to collect and prepare the data. This involves cleaning the data, removing any outliers, and normalizing the data so that it can be used by the machine learning algorithms.

Once the data has been prepared, it is then fed into the machine learning algorithms. The algorithms are trained to learn from the data and identify patterns that can be used to predict future failures. This training process can take a significant amount of time, depending on the amount of data and the complexity of the algorithms.

Once the algorithms have been trained, they can be used to predict future failures. This is done by feeding new data into the algorithms and using them to identify potential problems. The algorithms can then generate alerts or notifications to notify the manufacturer of potential problems.

Benefits of AI-Driven Predictive Maintenance

AI-driven predictive maintenance offers a number of benefits over traditional predictive maintenance methods. These benefits include:

- Improved accuracy: AI-powered solutions can learn from more data and identify more patterns than traditional methods, which can lead to improved accuracy in predicting equipment failures.

- Earlier detection: AI-powered solutions can identify potential problems earlier than traditional methods, which can give manufacturers more time to take action and prevent unplanned downtime.

- Reduced costs: AI-powered solutions can help to reduce maintenance costs by preventing unplanned downtime and identifying problems that can be fixed before they become serious.

Challenges of AI-Driven Predictive Maintenance

While AI-driven predictive maintenance offers a number of benefits, there are also a number of challenges associated with the technology. These challenges include:

- Data collection and preparation: Collecting and preparing data for use in AI-powered predictive maintenance solutions can be a significant challenge. This is especially true for manufacturers with a large number of assets or a wide variety of products.

- Algorithm development and training: Developing and training AI algorithms can be a complex and time-consuming process. This is especially true for manufacturers with complex assets or products.

- Deployment and integration: Deploying and integrating AI-powered predictive maintenance solutions can be a challenge. This is especially true for manufacturers with a large number of assets or a wide variety of products.

Conclusion

AI-driven predictive maintenance is a promising new technology that has the potential to revolutionize the way that manufacturers maintain their assets. By identifying potential problems before they occur, AI-powered predictive maintenance can help to prevent unplanned downtime and reduce maintenance costs. However, there are also a number of challenges associated with the technology, including data collection and preparation, algorithm development and training, and deployment and integration. As the technology continues to develop, these challenges are likely to be overcome, and AI-driven predictive maintenance will become an increasingly important tool for manufacturers.

How to Implement AI-Driven Predictive Maintenance

If you're interested in implementing AI-driven predictive maintenance in your manufacturing operation, here are a few steps to get started:

- Identify your goals. What do you hope to achieve by implementing AI-driven predictive maintenance? Do you want to reduce unplanned downtime? Improve asset reliability? Reduce maintenance costs? Once you know your goals, you

Post a Comment